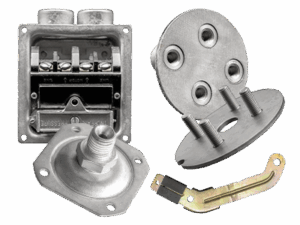

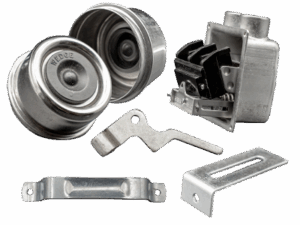

Progressive die metal stamping is an efficient manufacturing process that uses a continuous strip of metal fed through multiple stations within a single die. Each station performs a specific operation, such as cutting, punching, bending, or forming, until the finished part is completed.

This highly automated method is ideal for high-volume production and is widely used in industries like automotive, electronics, aerospace, and industrial manufacturing. Below are the key advantages of progressive die stamping and why it is a preferred solution for producing precise and cost-effective metal components.

Advantages of Progressive Die Metal Stamping

High-Speed Production

Progressive die stamping allows multiple operations to occur in one press cycle, enabling extremely fast production rates. This makes it ideal for large-scale manufacturing where speed and efficiency are critical.

Lower Costs

After the initial tooling investment, progressive die stamping significantly reduces labor costs and production time. The automation and continuous operation help keep the cost per unit low for high-volume runs.

High Precision

Because each part is produced using the same fixed tooling, progressive die stamping delivers tight tolerances and consistent quality. This reduces defects, rework, and variation between parts.

Complex Parts

Progressive dies can handle multiple forming and cutting operations in sequence, allowing manufacturers to produce complex geometries and detailed features within a single process.

Less Material Waste

Optimized strip layouts help maximize material usage and minimize scrap. This improves cost efficiency while also supporting more sustainable manufacturing practices.

Long Production Runs

Once the die is set up, progressive stamping can run continuously with minimal interruptions. This reduces downtime and increases overall productivity.

Consistent Results

Progressive die tooling is designed for durability, allowing manufacturers to maintain consistent output and quality even across long production cycles.