Sourcing Progressive Die Stamped Parts for Aerospace Industry

Aerospace manufacturing allows zero room for error. Every bracket, clip, and connector must meet strict specifications. Safety and performance depend on it. Original Equipment Manufacturers (OEMs) face a dual challenge. They need components that are flawless. They also need them produced in high volumes to keep assembly lines moving.

Progressive die stamped parts for aerospace industry provide the solution. This manufacturing method combines speed with extreme precision. It turns coils of metal into finished components in a single pass. However, not every stamping shop can handle aerospace work. It requires specific certifications, rigorous quality control, and the ability to work with difficult materials.

This article explores why progressive die stamping is critical for aerospace programs. It also covers what you should look for in a manufacturing partner.

The Role of Progressive Die Stamped Parts for Aerospace Industry

Aerospace projects often require thousands or millions of identical parts. Producing these one by one is too slow and expensive. Progressive die stamped parts for aerospace industry solves this by automating the process. A metal strip feeds through a press. Multiple stations perform cuts, bends, and punches simultaneously.

This process offers three specific benefits for aerospace applications:

- Repeatability: The die does not change between strokes. Part number 1 and part number 100,000 are identical. This consistency is vital for flight-critical hardware.

- Speed: High-speed presses can run hundreds of strokes per minute. This supports the production rates needed for large commercial and military programs.

- Cost Efficiency: Combining multiple operations into one tool reduces labor costs. It also reduces handling time. This lowers the price per part significantly over long production runs.

Critical Standard: AS9100 Rev. D Certification

You cannot source progressive die stamped parts for aerospace industry from a standard machine shop. The industry demands a higher level of quality management. The gold standard is AS9100 Rev. D.

This certification is not just a badge. It proves a manufacturer has processes in place to minimize risk and ensure traceability. Wedge Products is an experienced aerospace metal stamping company. We are fully certified to AS9100 Rev. D.

Our facility goes beyond basic compliance. We have a special aerospace team. We also have dedicated equipment and work areas specifically for meeting the requirements of our aerospace customers. This ensures that military and commercial flight components are handled with the correct protocols from start to finish.

From Design to Production: Capabilities That Matter

Aerospace components are complex. Producing them requires robust machinery and diverse capabilities.

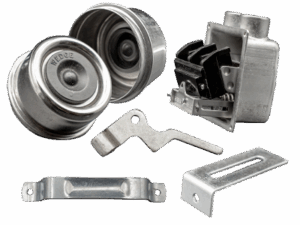

Press Capacity and Versatility

A versatile shop needs a range of press sizes. Wedge Products operates 64 presses ranging from 3 to 400 tons. This allows us to stamp small precision electronics as well as larger structural components. We handle high-volume progressive die stamping designed for accuracy and reliable part flow.

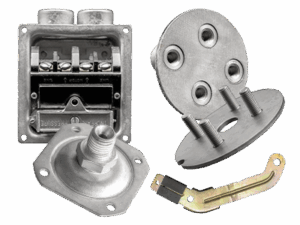

Deep Draw Stamping

Many aerospace parts are not flat. They are cylindrical or box-shaped. Examples include housings, caps, and enclosures. Deep draw stamping pulls metal into a die to create these shapes. Our deep draw services are ideal for fabricating aerospace components that require depth without sacrificing structural integrity.

Materials and Secondary Services

Stamping the part is only half the battle. Aerospace engineers select materials based on weight and strength. We commonly stamp aluminum, stainless steel, and other aerospace-grade alloys.

The part is rarely finished after it leaves the press. It usually requires secondary processing. Managing multiple vendors for these steps adds risk and delay. A full-service partner handles this for you.

Wedge Products coordinates a wide range of secondary services essential for aerospace parts:

- Heat Treating: To adjust the hardness and ductility of the metal.

- Anodizing and Plating: To provide corrosion resistance and surface durability.

- Non-Destructive Testing (NDT): This is critical for aerospace. It verifies the internal integrity of a part without damaging it.

- Custom Packaging: We provide custom individual packaging to ensure each part remains defect-free during shipment.

Why Partner with Wedge Products?

Supply chain stability is a major concern today. You need a partner who delivers production-ready parts on time. Wedge Products has been a trusted partner since 1933. We understand the specific demands of military and aerospace stamping.

We deliver fully finished components. We do not just supply raw stampings. This supports long-term demand and stable supply chains for OEM programs.

Sourcing progressive die stamped parts for the aerospace industry is about managing risk. You need a partner with the right equipment and the right certifications.

Wedge Products combines AS9100 Rev. D quality standards with the capacity of 64 presses. We ensure your components are accurate, repeatable, and ready for flight.