What Is the Progressive Die Stamping Process?

The progressive die stamping process is a highly efficient and precise method used to manufacture complex metal parts at high speed. This technique involves feeding a coil of metal strip through a set of progressively arranged tooling stations inside a die. At each station, the material experiences a specific forming action such as punching, bending, coining, or trimming until the final part is produced.

Because operations occur simultaneously as the strip advances, this method delivers exceptional consistency, repeatability, and fast cycle times for large production volumes.

How the Progressive Stamping Process Works

Progressive stamping combines multiple manufacturing steps into one continuous action. A typical cycle includes:

- Coil Feeding: A continuous roll of metal strip is loaded into the press.

- Progressive Stations: As the strip moves, each station performs a unique operation.

- Forming Actions: These can include blanking, piercing, embossing, bending, and more.

- Scrap Removal: Scrap slugs and carrier material are automatically removed to keep the strip advancing smoothly.

- Final Part Ejection: Completed components are separated from the carrier strip.

Advantages of the Progressive Metal Stamping Process

The progressive metal stamping process offers numerous benefits across industries, including:

- High Production Speed: Multiple operations in a single cycle dramatically increase output.

- Consistent Quality: Each part is formed under controlled conditions for uniform tolerance.

- Lower Production Cost: Automation reduces manual handling and waste.

- Design Flexibility: Tooling can be tailored for complex geometries.

- Material Efficiency: Optimized strip layout helps reduce scrap and improve overall material yield.

Because of these advantages, progressive stamping is common in automotive, electronics, aerospace, appliance manufacturing, and more.

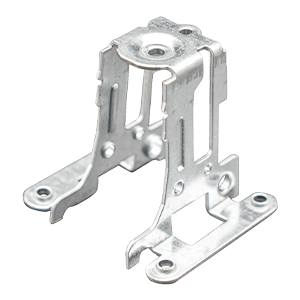

Progressive Die Tooling: What You Need to Know

Tooling is the heart of the progressive die process. A well‑engineered tool includes:

- Stations: Each designed for a specific function.

- Pilots/Guides: Ensure precise strip alignment.

- Cutting Edges: Hardened to maintain tool life.

- Stripper Plates and Springs: Control material release.

Applications and Uses

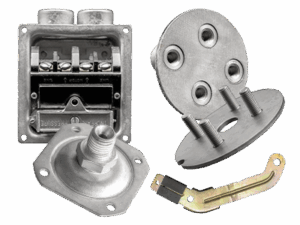

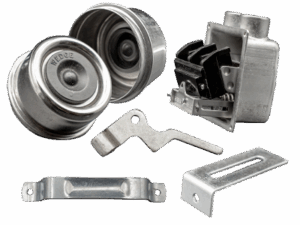

The progressive die process is ideal for producing:

- Washers, clips, brackets, and fasteners

- Electrical terminals and connectors

- Precision parts for automotive components

- A wide range of thin- to medium-gauge metal components

With the right tooling and material, the process can handle everything from light-gauge copper strips to heavier steel applications.

Best Practices for Efficient Progressive Stamping

- Choose the Right Material: Material hardness and formability influence tool wear and cycle time.

- Maintain Tooling Regularly: Scheduled inspections extend die life and prevent defects.

- Monitor Press Conditions: Ensure speed and stroke settings match job requirements.

- Optimize Strip Layout: Efficient nesting reduces waste and improves cost per part.

Partner with Wedge Products for Progressive Die Solutions

With over 85 years of metal stamping expertise, Wedge Products is a trusted supplier of high-precision components for critical industries. Our progressive die stamping capabilities are backed by in-house tooling design, rigorous quality control, and the experience to handle complex requirements.

Contact us today to learn how our progressive metal stamping solutions can support your production goals with precision, speed, and cost-efficiency.